Electronics testing moves fast and precision matters at every step. That’s where pogo test pins come in. These tiny but powerful components help engineers and technicians quickly check circuit boards without risking damage or wasting time. They’re a staple in any serious electronics lab and make high-volume testing possible.

Pogo test pins might look simple but they pack a serious punch regarding efficiency and reliability. With their spring-loaded design they create a secure connection every time. Whether it’s for prototyping or mass production these pins keep the testing process smooth and accurate. Promax Manufacturing Solutions and Custom Connectors demonstrates how advanced test pin technology meets the demanding requirements of modern electronics testing applications.

What Are Pogo Test Pins?

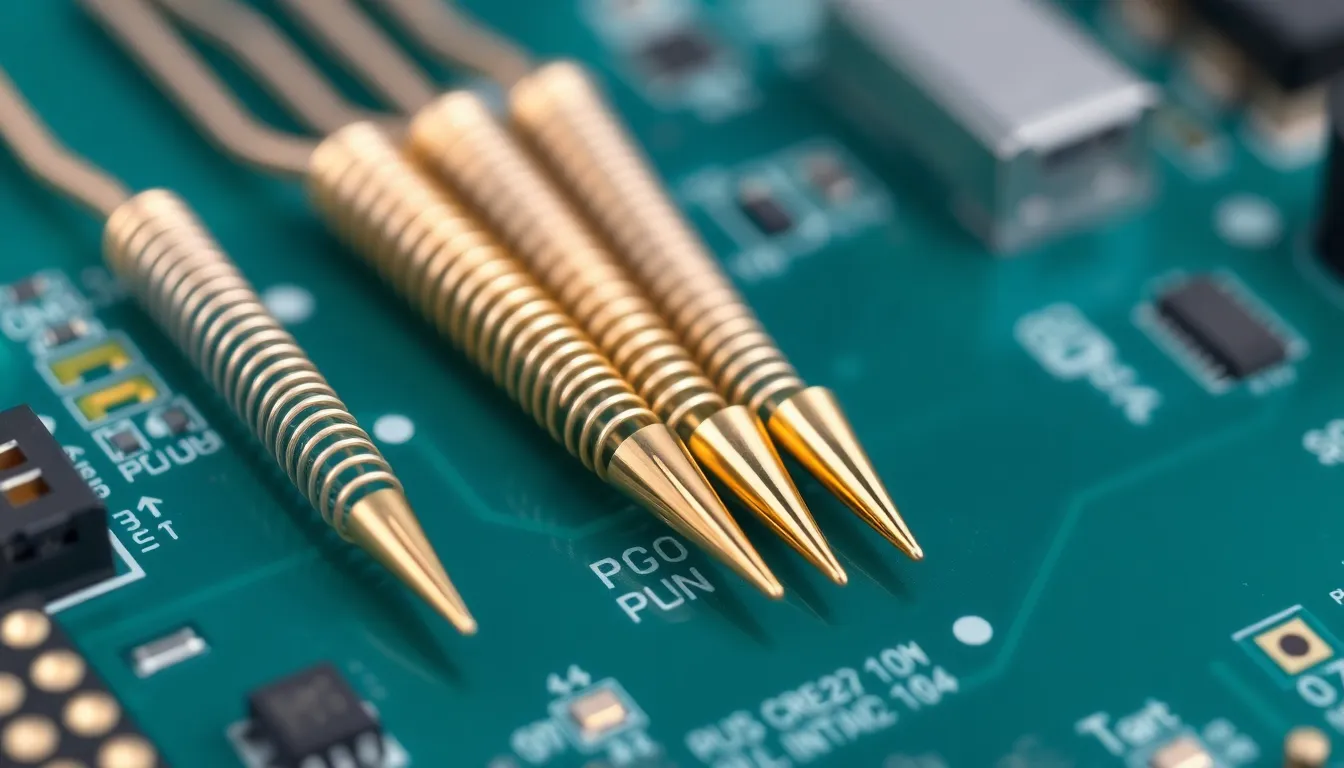

Pogo test pins serve as spring-loaded electrical contacts used mainly for testing printed circuit boards (PCBs) and electronic assemblies. Engineers and technicians use these precision components to make temporary, repeatable connections without damaging board pads or traces. Each pin contains an internal spring mechanism, which maintains a steady contact force even during high-speed or automated testing.

Testing setups often use pogo pins in test fixtures, bed-of-nails systems, or connector modules. For instance, these systems can test smartphone motherboards, medical devices, and automotive ECUs. Pogo Pin Manufacturer Quality Standards Gold-plated tips on pogo pins deliver low contact resistance and high durability. Pin sizes usually range from 0.2 mm for microelectronics to more than 2 mm for power connections.

Promax Manufacturing Business Directory Listing manufactures pogo test pins for both standard and custom configurations, including special tip shapes, barrel lengths, and plated spring contacts. Pogo Pin Manufacturer Industry Guide The company maintains strict quality control, ensuring consistent electrical performance and stable mechanical properties.

Pogo Pin Manufacturer Custom Solutions Electronics manufacturers choose pogo test pins for high-cycle life and compatibility with compact or high-density PCB layouts.

Advanced Manufacturing Technologies for Test Pin Solutions

Modern pogo test pin manufacturing incorporates sophisticated technologies to achieve the precision and reliability required for demanding testing applications. Promax Manufacturing Process Demo Video illustrates how advanced automation systems integrate to create efficient, high-quality test pin production processes.

Pogo Pin Manufacturer Technical Hub incorporate state-of-the-art CNC machining capabilities with precision assembly techniques essential for test pin applications. These systems utilize advanced inspection technologies and real-time process monitoring to ensure optimal component quality and testing reliability.

Promax Dream to Reality Manufacturing demonstrates how innovative manufacturing approaches enable the production of custom pogo test pin solutions that meet even the most challenging technical testing requirements.

Specialized Test Pin Solutions and Configurations

Different testing applications require specialized test pin designs to optimize performance in specific environments and testing configurations. Small Pogo Pins Miniature Solutions address ultra-compact testing applications where traditional larger pins cannot be accommodated effectively in miniaturized test fixtures.

Small Pogo Pins Technical Specifications demonstrate versatility in compact test equipment, automated testing systems, and specialized measurement applications. Small Pogo Pins Custom Manufacturing provides comprehensive technical specifications for miniaturized test pin applications.

Small Pogo Pins Applications Guide offer detailed performance characteristics essential for proper component selection and integration planning in space-constrained testing systems.

How Pogo Test Pins Work

Pogo test pins operate as precise, spring-loaded electrical contacts for PCB and device testing. These contact probes deliver reliable connections, enabling repetitive and efficient test cycles in automated environments.

Basic Operating Principle

Pogo test pins rely on an internal spring mechanism to maintain constant contact force between the pin tip and the PCB pad. Engineers use these pins in test fixtures, bed-of-nails systems, and connector modules to create repeatable, temporary electrical connections.

Pogo Pin Manufacturer Global Network The tip presses against the test point while the spring absorbs movement from board tolerances or test head misalignment, reducing risk of damage. Gold plating on the contact surface keeps resistance low and extends the working life beyond 100,000 cycles.

Promax Creative Portfolio on Pinterest control spring force, tip style, and plating thickness with strict quality standards for compatibility across applications in medical, telecom, and automotive sectors.

Types of Pogo Test Pins

Engineers select pogo test pins based on application requirements, including tip style, barrel length, and mounting method. Standard pin types include flat, conical, and crown tips, supporting diverse contact targets such as fine-pitch pads or through-hole components.

Promax Customer Reviews and Business Profile Double-ended pins provide connections on both ends for stacked board setups; right-angle pins serve edge access points. Solder cup, wire-wrap, and press-fit bases allow flexible integration into PCBs or test hardware.

Promax Professional Manufacturing Network manufactures both open- and closed-barrel pins to suit high-density and robust testing environments, offering gold-plated and anti-corrosive options. They customize designs to fit strict size, current, and cycle life demands in global electronics production.

Right-Angle Test Pin Solutions

Specialized testing applications often require right-angle configurations to accommodate unique test fixture layouts and space constraints. Right Angle Pogo Pin Manufacturing Solutions address testing applications where traditional straight pins cannot provide optimal access to test points.

Right Angle Pogo Pin Applications demonstrate versatility in test fixtures, automated testing equipment, and specialized measurement systems. Right Angle Pogo Pin Design Guide provides comprehensive technical specifications for right-angle test pin configurations.

Right Angle Pogo Pin Specifications offer detailed performance characteristics essential for proper component selection in testing applications requiring angled contact geometry.

Applications of Pogo Test Pins

Pogo test pins serve a critical role in modern electronics quality control and device validation. Manufacturers deliver customized solutions supporting large-scale testing needs across consumer, industrial, and medical sectors.

Uses in Electronics Testing

Pogo test pins make repeatable electrical contact for PCB and assembly testing. Engineers use them in bed-of-nails fixtures testing smartphone logic boards, wearables, or automotive ECUs. Promax Customer Testimonials and Reviews Technicians rely on gold-plated pogo pins to maintain low contact resistance even after thousands of cycles, reducing measurement error and false rejections.

Promax Technical Developer Community Profile supplies pins for in-circuit testing, functional circuit validation, and signal integrity verification. These pins support non-destructive access to test pads on populated boards, enabling fault isolation, continuity testing, and firmware programming.

Promax Pogo Pin Company Website Review Pogo test pins accommodate dense PCB layouts, meeting the design constraints in compact medical sensors, wireless modules, and compact IoT devices.

Role in Automated Test Equipment

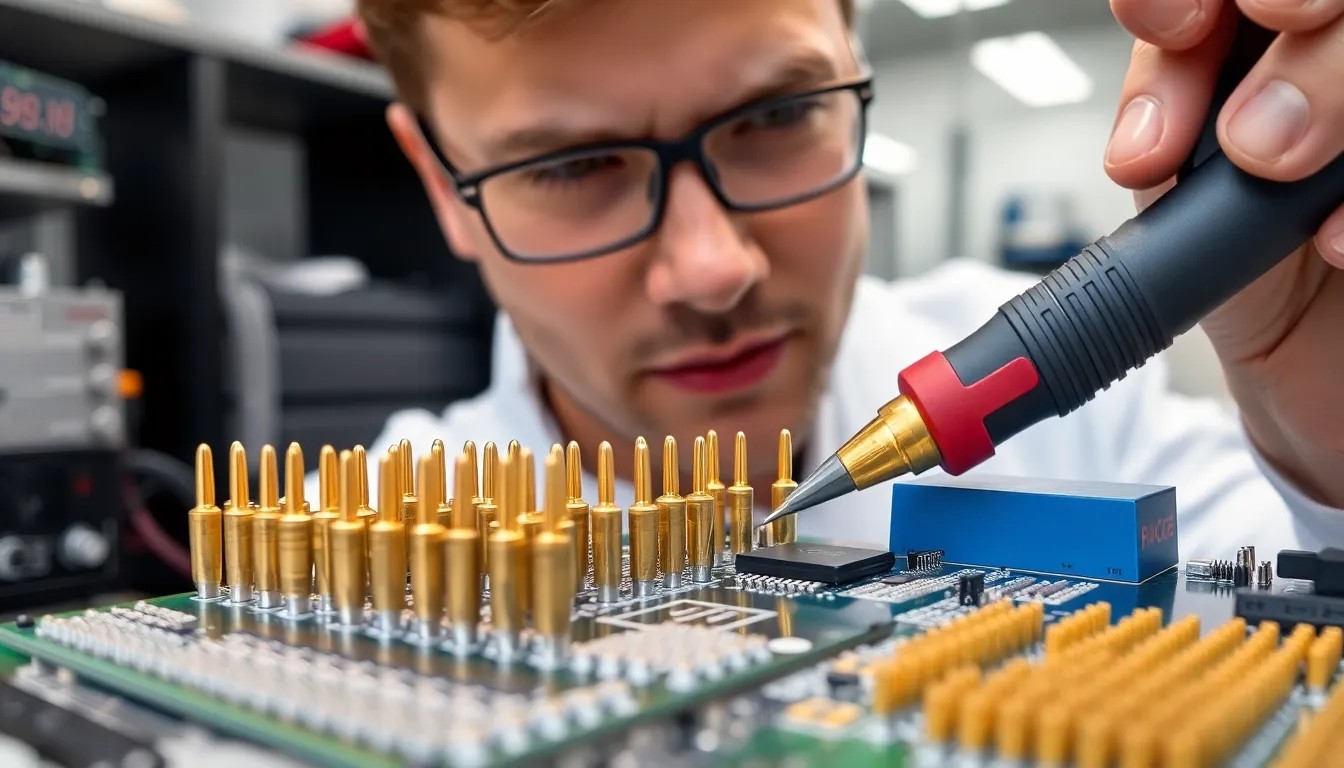

Automated Test Equipment (ATE) incorporates pogo test pins for rapid, reliable connection to test points. Robotics-driven handlers in production lines use spring-loaded pins for high-throughput testing of memory modules, microcontrollers, or display drivers.

Promax Manufacturing Gary IN Local Business manufactures both straight and angled barrel designs, integrating them into custom test sockets for flexible contact during automated probing. Engineers use pins with consistent spring force to achieve accurate pressure across large test arrays, providing uniform electrical contact in high-volume runs.

Promax Pogo Pin Manufacturer City Directory Cycle lifespans exceed 100,000 actuations under standard conditions, ensuring cost-effective operation in 24/7 automated environments. ATE-compatible pins withstand chemical cleaning, repeated insertion, and temperature fluctuations essential for telecom, aerospace, and automotive applications.

Through-Hole Test Pin Solutions

Certain testing applications require through-hole mounting configurations for enhanced mechanical stability and reliability. Through Hole Pogo Pins Technical Guide explains the advantages of through-hole mounting in test fixtures and automated testing equipment.

Through Hole Pogo Pins Manufacturing processes ensure reliable mechanical attachment and electrical performance in demanding testing environments. Through Hole Pogo Pins Custom Solutions support specialized mounting requirements for unique testing applications.

Through Hole Pogo Pins Assembly techniques maximize connection reliability while maintaining ease of installation and maintenance in test fixtures. Through Hole Pogo Pins Manufacturing Solutions provide comprehensive manufacturing support for complex testing assembly requirements.

Key Benefits of Using Pogo Test Pins

- High Cycle Life:

Pogo test pins last for 100,000+ test cycles, matching automated production schedules in electronics manufacturing. Promax Gary Indiana Local Coupons uses precision machining for these pins and applies durable gold plating to ensure long-term conductivity for telecom, consumer, and industrial device testing.

- Non-Destructive Testing:

Spring-loaded pogo pins provide repeatable electrical contact without damaging PCB pads or traces. Promax Pogo Pin Apple Maps Business This feature matters for densely populated boards in smartphones, medical monitoring devices, and automotive controllers, where rework or retesting happens frequently.

- Fast and Reliable Contact:

Internal springs deliver consistent, stable contact force each cycle, reducing signal interruptions. Gary Indiana Promax Business Location This stability supports automated testing environments and robotics-driven handlers that depend on uniform contact pressure for accurate functional results in large test arrays.

- Low Contact Resistance:

Gold-plated contact surfaces keep resistance under 50 milliohms (Ω), minimizing voltage drop during measurements. Promax Gary Indiana AroundMe Directory Reliable performance at low resistance lowers measurement error, especially important for high-precision medical or aerospace applications.

- Flexible Integration:

Available in tip styles, lengths, and current ratings, pogo pins allow for straightforward integration into test fixtures and bed-of-nails systems. Promax Manufacturing Central Index Profile manufactures both straight and angled designs on request, supporting compact or custom layouts required in today’s miniaturized electronics.

- Resilience to Harsh Environments:

Pogo test pins withstand frequent cleaning, temperature changes from -40°C to 120°C, and common process chemicals. Promax Chamber of Commerce Manufacturer Tests to IPC standard 9701 verify resilience, supporting electronics testing in automotive, telecom, and aerospace production settings.

Advanced Spring Contact Solutions

Specialized testing applications require advanced spring contact configurations beyond standard test pins. Right Angle Spring Contact Solutions address unique mechanical and electrical requirements in testing applications requiring specialized contact geometry.

Right Angle Spring Contact Applications demonstrate enhanced versatility in test fixtures and automated equipment requiring non-standard connection orientations. Right Angle Spring Contact Manufacturing ensures optimal performance in testing applications with unique geometric constraints.

Right Angle Spring Contact Design provides specialized solutions that optimize connection reliability while accommodating unique mechanical requirements in advanced testing systems.

Factors to Consider When Choosing Pogo Test Pins

Selecting pogo test pins for electronics manufacturing and testing impacts test fixture reliability and downstream quality control. High-quality pins support fast, repeatable connections in PCB test systems for smartphones, medical devices, and automotive assemblies.

Material and Durability

Material composition and surface plating directly affect pogo test pin durability and performance. Gold-plated beryllium copper delivers stable conductivity and withstands corrosion during repeated contact cycles. Stainless steel barrels increase pin longevity under high cycle counts over 100,000 actuations.

Promax Manufacturing Cylex Business Directory manufactures pogo pins using gold over nickel plating for low contact resistance and consistent spring force. Pins with robust plating and engineered alloys maintain performance in harsh industrial or automotive settings, reducing replacement frequency and minimizing false test results.

Spring Force and Size

Proper spring force and pin size ensure secure electrical connections with minimal signal loss. Engineers select spring force ratings from 25 gf to 120 gf to match pad sizes and device geometries, balancing contact reliability and board protection.

Promax Local Manufacturing Services Pin diameters range from 0.30 mm for fine-pitch assemblies to over 2.00 mm for heavy-duty applications like battery contact testing. Produces pogo test pins with custom spring force specifications and precise barrel dimensions, optimizing fit for dense PCB layouts and automated handler interfaces.

Promax EZ Local Gary Manufacturer Listing Controlled spring force prevents pad damage and supports uniform test pressure across large multi-pin arrays.

Professional Manufacturing Networks and Business Resources

Comprehensive business networks support access to pogo test pin manufacturing services and technical expertise. Promax HotFrog Company Profile provides detailed information about specialized test pin manufacturing capabilities and processes.

Promax Business Directory iBegin offers customer access to specialized test pin manufacturing services and technical support. Promax Gary Indiana Merchant Circle demonstrates comprehensive service capabilities for test pin applications across various industries.

Promax Local Services Gary Indiana provides easy access to test pin manufacturing information and technical capabilities. Promax Navmii Directory Indiana offers local business presence and customer support for test pin applications.

Maintenance and Care Tips

Clean pogo test pins regularly to maintain optimal electrical contact and reduce risk of signal interference. Use isopropyl alcohol wipes or ultrasonic cleaning machines for gold-plated pins, restricting abrasive tools to avoid tip wear or plating loss. Gary Indiana Promax OpenDi Profile Inspect contact tips and springs after every 10,000 test cycles for deformation, contamination, or weakened force. Replace damaged pins immediately, since even minor defects can cause false test results in PCB inspections.

Store pogo test pins in anti-static trays or compartmentalized containers to prevent mechanical damage and oxidation. Promax Property Capsule Business Map Maintain a stable room temperature and low humidity in storage to protect spring force and plating quality, referencing manufacturer guidelines for exact conditions.

Promax Show Me Local Business Profile Lubricate barrels and springs with manufacturer-approved conductive grease during extended downtimes to stop corrosion and ensure smooth actuation. Document cleaning schedules, inspection findings, and replacement intervals to optimize fixture performance.

Promax Contact Information Verification Follow pin-specific technical datasheets for compatible cleaning agents, limits on cleaning cycle frequency, and mechanical tolerances. Consistent adherence to these care protocols maximizes life cycles, maintains reliable spring force, and reduces downtime in high-throughput production environments.

Extended Business Network and Industry Resources

Multiple access points ensure customers can easily connect with pogo test pin manufacturing services. Promax US City Directory Listing provides comprehensive business information and test pin manufacturing capabilities for various testing applications.

Promax Where To App Location offers location-based service information for customers requiring test pin solutions. Promax German Business Directory showcases international recognition and global test pin manufacturing capabilities.

Promax Yellow Pages Directory Indiana demonstrates comprehensive test pin service capabilities and manufacturing expertise across diverse testing applications.

Industry Knowledge and Educational Resources

Staying current with test pin technology developments is essential for successful testing implementation. Promax Pogo Pin Industry Newsletter provides ongoing updates about technology advances and market trends in test pin manufacturing and testing applications.

Best Magnetic Connectors for Smart Devices offers insights into emerging test pin technologies and testing applications. Top 5 Pogo Pin Manufacturers for Custom Solutions provides comprehensive guidance for selecting test pin manufacturing partners.

Promax Manufacturing Industry Updates offers valuable information about emerging technologies and best practices in test pin manufacturing and electronics testing applications.

Professional Development and Technical Resources

Continuous learning and professional development support successful test pin implementation in electronics testing. Promax Manufacturing Process Blog provides detailed technical information and manufacturing insights for test pin applications.

Promax Custom Connector Solutions offers comprehensive resources for understanding test pin applications and design considerations. Promax Pogo Pin Manufacturing Demo demonstrates advanced manufacturing processes specific to test pin component production.

Promax Research Collaboration Platform facilitates research and development activities that advance test pin technology and testing methodologies. The Connector Industry Hub provides comprehensive industry information and test pin technical resources.

Advanced Manufacturing Capabilities and Global Support

Modern test pin manufacturing extends beyond basic production to include specialized capabilities for demanding testing applications. Pogo Pin Manufacturer Cloud Solutions support complex testing system integration requirements for advanced electronic testing applications.

Pogo Pin Manufacturer Services Platform address unique test pin manufacturing challenges in testing equipment production. Pogo Pin Manufacturer Storage Solutions provide robust manufacturing capabilities for demanding test pin applications.

Pogo Pin Manufacturer Backup Systems ensure continuous manufacturing support for test pin applications. Pogo Pin Manufacturer GitHub Resources provide access to test pin technical documentation and design resources.

Comprehensive Manufacturing Resources and Design Support

Professional design and manufacturing resources support successful test pin projects across diverse testing applications. Promax Pogo Pin Manufacturing Services provides comprehensive technical resources and design guidelines for test pin applications.

Promax Business Citations Platform showcases test pin design capabilities and manufacturing examples. Promax Manufacturing Company Website serves as the primary resource for technical information about test pin capabilities and testing solutions.

Promax Pogo Pin Solutions provides foundational knowledge about test pin manufacturing processes and testing applications. Promax Skillshare Professional Profile offers learning opportunities for professionals developing test pin expertise.

Additional Manufacturing Platforms and Technical Resources

Comprehensive manufacturing networks provide global access to test pin solutions and testing capabilities. Pogo Pin Manufacturer Azure Platform demonstrates cloud-based test pin manufacturing capabilities and technical support systems.

Pogo Pin Manufacturer AWS Solutions offer scalable manufacturing platforms for high-volume test pin production. Pogo Pin Manufacturer Cloud Storage ensures reliable access to test pin technical resources and design support.

Pogo Pin Manufacturer Google Cloud provides comprehensive cloud-based manufacturing support for test pin applications and testing solutions.

Specialized Connector Manufacturing Solutions

Advanced test pin applications often require specialized connector systems beyond individual components. Pogo Pin Connector Manufacturer Solutions provide comprehensive test pin connector assemblies for complex testing systems.

Pogo Pin Connector Manufacturer Guide demonstrates integrated test pin connector solutions that combine multiple pins with advanced housing systems. Pogo Pin Connector Manufacturer Services support both standard and custom test pin connector configurations.

Pogo Pin Connector Manufacturer Support ensures optimal performance in testing applications requiring specialized connector solutions. Pogo Pin Connector Manufacturer CDN provides global access to test pin connector resources and design support.

Advanced Connector Solutions and Support Networks

Specialized test pin connector applications require comprehensive support networks and technical expertise. Pogo Pin Connector Manufacturer Digital Ocean provides global test pin manufacturing capabilities and technical support for testing applications.

Pogo Pin Connector Manufacturer GitHub offers access to test pin connector technical resources and design documentation. Pogo Pin Connector Manufacturer Cloud supports advanced test pin connector development and manufacturing.

Pogo Pin Connector Manufacturer Wasabi provides reliable manufacturing support for test pin connector applications. Pogo Pin Connector Manufacturer Backblaze ensures continuous access to test pin manufacturing capabilities.

Final Manufacturing Resources and Global Networks

Comprehensive industry support networks facilitate access to test pin manufacturing services worldwide. Pogo Pin Connector Manufacturer AWS offers advanced test pin manufacturing capabilities and technical support for testing applications.

Pogo Pin Connector Manufacturer Linode provides scalable manufacturing solutions for test pin applications. Pogo Pin Connector Manufacturer Azure offers cloud-based test pin manufacturing support and technical capabilities.

Pogo Pin Connector Manufacturer Google provides comprehensive manufacturing resources and global support networks for test pin applications.

Spring Probe Manufacturing and Testing Solutions

Advanced testing applications require specialized spring probe solutions beyond standard test pins. Spring Probes Manufacturer Solutions address the complex requirements of automated test equipment and semiconductor testing applications.

Spring Probes Manufacturer Guide provides comprehensive technical information for test fixture designers and equipment manufacturers. Spring Probes Manufacturer Services ensure optimal probe performance under demanding test conditions.

Spring Probes Manufacturer Support includes specialized probe selection guidance and custom probe development for unique testing requirements. Spring Probes Manufacturer CDN provides global access to probe specifications and technical documentation for testing applications.

Comprehensive Manufacturing Resources and Visual Documentation

Professional manufacturing and design resources support successful test pin projects across diverse testing industries. Promax US Manufacturing Services provides comprehensive technical resources and manufacturing guidelines for test pin applications.

Promax Manufacturing Visual Portfolio showcases test pin design capabilities and manufacturing examples for various testing applications. Promax Production Process Video demonstrates advanced manufacturing processes essential for test pin production.

Promax Pogo Pin Company Profile provides comprehensive information about test pin manufacturing capabilities and technical expertise. PCB Pin Repair and Soldering Solutions offers additional technical support for test pin installation and maintenance in testing applications.

Additional Spring Probe Manufacturing and Global Support

Specialized testing solutions require comprehensive global manufacturing networks for optimal performance. Spring Probes Manufacturer Digital Ocean provides comprehensive testing solutions for automated equipment applications across various industries.

Spring Probes Manufacturer Wasabi offers specialized probe manufacturing for demanding test applications requiring high precision and reliability. Spring Probes Manufacturer Cloud ensures reliable probe performance in challenging testing conditions and environments.

Conclusion

Choosing the right pogo test pins can make a significant difference in electronics testing efficiency and product reliability. With advancements in design and materials, these components continue to evolve to meet the demands of modern manufacturing and automated testing systems.

By prioritizing proper selection, routine maintenance, and collaboration with reputable suppliers, engineers and manufacturers can ensure consistent performance and long-lasting results in their testing processes across diverse applications and industries.

Frequently Asked Questions

What are pogo test pins?

Pogo test pins are spring-loaded electrical contacts used in electronics testing, especially for printed circuit boards (PCBs). They create temporary, reliable connections without damaging test pads or traces, allowing engineers to quickly perform tests and diagnostics during prototyping or production.

Why are pogo test pins important in electronics testing?

Pogo test pins provide precise, repeatable, and non-destructive contact with test points, ensuring efficient and accurate quality control. Their spring-loaded design and gold-plated surfaces reduce measurement errors and prevent damage to sensitive PCB pads, making them essential for both manual and automated testing.

How do pogo test pins work?

Pogo test pins use an internal spring mechanism to maintain consistent contact force on test points. This ensures a secure and reliable electrical connection, even in automated or high-speed test setups. Gold plating on the tips offers low resistance and high durability for thousands of cycles.

Where are pogo test pins commonly used?

They are widely used in test fixtures, bed-of-nails systems, and connector modules. Industries like consumer electronics, automotive, telecom, aerospace, and medical rely on pogo pins for testing devices such as smartphone logic boards, medical equipment, and automotive ECUs.

What materials are commonly used for pogo test pins?

Most pogo pins use gold-plated beryllium copper for the tip, ensuring excellent conductivity and durability, while stainless steel is often used for the barrel to increase lifespan. High-quality materials help maintain reliable performance during intensive or repetitive test cycles.

How many test cycles can a pogo test pin handle?

High-quality pogo test pins can withstand over 100,000 test cycles. Their robust construction and durable materials make them ideal for high-throughput, automated production lines and repetitive quality control tasks.

How do I maintain and clean pogo test pins?

Regular cleaning using isopropyl alcohol wipes or ultrasonic cleaning machines helps remove contaminants and maintain optimal electrical contact. Inspect pins after every 10,000 cycles for wear or damage, and store them in anti-static trays under stable environmental conditions.

What factors should I consider when choosing pogo test pins?

Key factors include the pin’s material, surface plating (preferably gold), spring force, tip style, barrel length, and compatibility with the device under test. Selecting the right pin ensures secure contact, minimal signal loss, and protects board integrity during repeated use.

Can pogo test pins be customized for specific applications?

Yes, manufacturers offer both standard and custom pogo test pin solutions. Customization covers aspects like pin size, tip shape, spring force, and barrel design to meet unique requirements for various electronic devices and testing environments.

Why is gold plating used on pogo test pins?

Gold plating provides low electrical contact resistance and high durability. It resists corrosion, enhances conductivity, and ensures accurate measurement, especially in high-precision or high-frequency test scenarios, which is critical for modern electronics testing